Improving Contact Tip Work Distance CTWD Arc Length

The Contact Tip to Work Distance (CTWD) or Arc Length can be very difficult to execute properly when first learning to weld. The key to a good score on the VRTEX for CTWD or Arc length is watching the puddle and listening to arc sound. The body positioning and a visual cue can help guide a new welder to a successful outcome.

Here are a few pointers to assist in movement and welding technique.

1. Place the non-welding hand gently on the table and use it to guide the welding hand down the weld. Keep a light pressure on the table so the hand can slide across the table but not so light the body sways. The swaying of the body can cause the CTWD or Arc Length to change. Keeping a steady arc is the key to executing the correct CTWD or Arc length, which will improve the VRTEX score. Remember to keep the non-welding hand far enough away from the gas nozzle or electrode to prevent burns during actual welding.

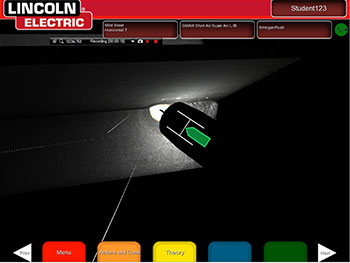

2. Use the CTWD or Arc Length visual cue to assist in obtaining proper distance. The visual cue teaches the proper distance by providing a gage that represents the in and out movement of the arc as shown in Figure 2. Sound is also key indicator for correct CTWD or Arc Length. Watch the visual cue and relate the sound to the proper distances.

When using two hands, the non-welding hand can force the wrist to roll which can affect the CTWD or Arc length and the work and travel angles as shown in Figure 4. Sometime putting too much pressure on the table with the non-welding hand can cause the wrist to roll also.