Common Design Mistakes in Aluminum

Background

As a rule, designers of metallic structures have learned to design using steel. When designing with aluminum, however, the engineer must not base the design on prior experiences with steel or any other material. The alloy selection, proper joint design and the choice of an optimal welding process may all be a function of the base material. While aluminum obviously obeys the same laws of mechanics as all other materials, it must be approached differently than steel when welded. Aluminum structures are not necessarily more difficult to design or weld than steel structures, they are just different.

Don’t Just Choose the Strongest Alloy

Aluminum is often chosen as a structural material for applications in which weight savings are important. Very often, the designer will choose the very strongest alloy available. This is a poor design practice for several reasons. First, the critical design limitation for many structures often is deflection, not strength. In such cases, the modulus of elasticity, not the tensile properties, will govern the design. The modulus of most aluminum alloys, weak and strong alike, is approximately the same (one-third the modulus of elasticity of steel), so no benefit accrues from using the strongest alloy. Second, and most importantly, many of the strongest aluminum alloys are not weldable using conventional techniques.

When we speak about aluminum alloys being "weldable" or "non-weldable," we are usually referring to the alloy’s ability to be welded without hot cracking. Alloys that are extremely susceptible to hot cracking are not considered appropriate for structural (load-carrying) applications, and are generally put in the non-weldable category. Hot cracking in aluminum alloys is primarily due to the chemistry of the alloy and the weld bead. For virtually every alloying addition, the cracking sensitivity varies as alloy content increases as shown in Figure 1. Weldable alloys have a composition that falls either well above or well below the maximum cracking sensitivity. In some cases, such as that of 6061, which is very crack-sensitive if welded without filler material, the weld cracking sensitivity can be reduced to acceptable levels with the addition of a high silicon or high magnesium filler metal. The additional silicon or magnesium pushes the solidifying weld metal below the cracking sensitivity level. In other alloys, such as 7075, it is not possible to design a weld filler alloy that results in a crack-resistant chemistry. These are considered to be non-weldable.

Alloys are broken into two groups: heat-treatable alloys and non-heat-treatable alloys. A relative assessment of weldability is also given for each of these.

The non-heat-treatable alloys are composed of the 1XXX, 3XXX, 4XXX, and 5XXX series. It is not possible to strengthen these alloys by heat treatment. They can only be strengthened by cold working (also called strain hardening). The 1XXX alloys, such as 1100, 1188, or 1350, are essentially pure aluminum (99+% purity). They are relatively soft and weak, with good corrosion resistance, and are usually used where high electrical conductivity is required, such as for bus bars or as electrical conductors. They are also used in certain applications that require a high degree of resistance to corrosion. All of these alloys are readily weldable.

The 3XXX series of alloys have various levels of manganese (Mn) added to strengthen them and improve their response to cold work. They are of moderate strength, have good corrosion resistance, and are readily weldable. They are used for air conditioning and refrigeration systems, non-structural building trim, and other applications.

The 4XXX series of alloys have silicon (Si) added as an alloying element to reduce the melting point and increase their fluidity in the molten state. These alloys are used for welding and brazing filler materials and for sand and die castings. They are the least crack-sensitive of all the aluminum alloys.

The 5XXX series of alloys have magnesium (Mg) added in order to increase their strength and ability to work-harden. They are generally very corrosion resistant and have the highest strengths of any of the non-heat-treatable alloys. Increasing magnesium content in these alloys results in increasing strength levels. These alloys are commonly available in the form of sheet, plate and strip, and are the most common structural aluminum alloys. They are generally not available as extruded sections, because they are expensive to extrude. They are readily weldable, in most cases, with or without filler metal. However, there is an Al-Mg cracking peak at approximately 2.5% Mg, so care must be used in welding alloys such as 5052. It should not be welded autogenously (i.e., without adding filler metal). Weld filler metal with a high Mg content, such as 5356, should be used to reduce the crack sensitivity.

The heat-treatable alloys are contained in the 2XXX, 6XXX, and 7XXX alloy families. The 2XXX family of alloys are high strength Al-Cu alloys used mainly for aerospace applications. In some environments, they can exhibit poor corrosion resistance. In general, most alloys in this series are considered non-weldable. A prime example of a non-weldable alloy in this series, which is attractive to designers because of its high strength, is alloy 2024. This alloy is commonly used in airframes, where it is almost always riveted. It is extremely crack-sensitive and almost impossible to weld successfully using standard techniques.

Only two common structural alloys in the 2XXX series are weldable: 2219 and 2519. Alloy 2219 is very easily weldable and has been extensively welded in fabricating the external tanks for the U.S. space shuttle. This alloy gets its good weldability because of its higher copper content, approximately 6%. A closely related alloy, which is also very weldable, is 2519. It was developed for fabrication of armored vehicles. Although there are detailed exceptions to this rule, the designer should probably consider all other alloys in the 2XXX series to be non-weldable.

The 6XXX series of alloys are the alloys probably most often encountered in structural work. They are relatively strong (although not as strong as the 2XXX or 7XXX series) and have good corrosion resistance. They are most often supplied as extrusions. In fact, if the designer specifies an extrusion, it will almost certainly be supplied as a 6XXX alloy. 6XXX alloys may also be supplied as sheet, plate and bar, and are the most common heat treatable structural alloys. Although all alloys in this series tend to be crack-sensitive, they are all considered weldable and are, in fact, welded every day. However, the correct weld filler metal must be used to eliminate cracking. Additionally, these alloys will usually crack if they are welded either without, or with insufficient, filler metal additions.

The 7XXX alloys are the ones that usually trip designers up. They are the very high strength Al-Zn or Al-Zn-Mg-Cu alloys that are often used in aerospace fabrication, and are supplied in the form of sheet, plate, forgings, and bar, as well as extrusions. With the few exceptions noted below, the designer should assume that the 7XXX alloys are non-weldable. The most common of these alloys is 7075, which should never be welded for structural applications. In addition, these alloys often suffer from poor corrosion performance in many environments.

A few of the 7XXX series defy the general rule and are weldable. These are alloys 7003 and 7005, which are often seen as extrusions, and 7039, which is most often seen as sheet or plate. Some common uses of these alloys today are bicycle frames and baseball bats, both of which are welded. These alloys are easily welded and can sometimes offer strength advantages in the as-welded condition over the 6XXX and 5XXX alloys.

There is one other exception to the general rule that 2XXX and 7XXX alloys are unweldable. There are a number of thick cast and/or wrought plate alloys designed as mold plate material for the injection molding industry. These alloys, which include Alca Plus, Alca Max, and QC-7, are all very close in chemistry to 7075 or 2618. The designer should absolutely avoid structural welds on these alloys. However, welding is often performed on these alloys to correct machining mistakes, die erosion, etc. This is acceptable because there are only low stresses on such welds and, in fact, the weld is often in compression.

This discussion has tried to make a few points:

First, when designing a structure of any kind, don’t scroll through the nearest list of aluminum alloys and pick the strongest

Realize that some alloys, often the stronger ones, are non-weldable. Make sure the selected alloy is readily weldable

Recognize that some alloys or alloy families are more suitable for some applications than others

One more caveat: when welding aluminum, the designer must not assume that the properties of the starting material and the properties of the weld are equivalent.

View Lincoln Electric Aluminum MIG and TIG Welding Products

Why Isn’t the Weld as Strong as the Original Base Metal?

A designer of steel structures generally assumes that a weld is as strong as the parent material, and the welding engineer who is responsible for fabricating the structure expects to make a weld which is as strong as the steel being used. It would be tempting to assume that the situation is the same when designing and fabricating aluminum structures, but it isn’t. In most cases, a weld in an aluminum alloy is weaker, often to a significant degree, than the alloy being welded.

Non-Heat-Treatable Alloys

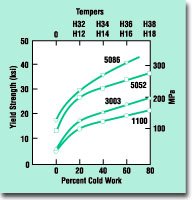

Alloys in this category (i.e., 1XXX, 3XXX, 4XXX, and 5XXX families) are produced by a cold working process: rolling, drawing, etc. After the cold working process, the alloy is given the designation of an F temper (as-fabricated). Alloys are then often given a subsequent annealing heat treatment, after which they are classified as an O temper (annealed). Many alloys are sold in this condition. Thus the correct designation for a plate of 5083 which was annealed after rolling is 5083 – O. One of the attractive properties of these alloys is that they can be significantly increased in strength if they are cold worked after annealing. Figure 2 shows what happens to several alloys with varying amounts of cold work. For example, alloy 5086 rises in yield strength from approximately 18 ksi (125 MPa) to 40 ksi (275 MPa) and is now said to be strain-hardened. A complete designation for this alloy would be 5056-H36. The H temper designation can be somewhat complicated, since it is used to designate a number of processing variables. However, the last digit designates the level of cold working in the alloy, with 9 denoting the highest.

A common mistake in designing welded structures using non-heat-treatable alloys is to look down a list of properties, disregard the O temper material, and choose an alloy of the highest temper because it is significantly stronger. This would seem to make sense, but it often doesn’t, because the heat of welding acts as a local annealing operation, significantly weakening the heat affected zone (HAZ) of the weld. If one plots the yield or tensile stress versus distance from the weld, a curve such as that seen in Figure 3 is obtained. If the design is based on the strain hardened properties, the allowable design stress will usually be above the actual yield point of the HAZ. Although it may seem counter-intuitive, the fact is this: No matter what temper one starts with, the properties in the HAZ will be those of the O temper annealed material due to the welding operation. Therefore, the design must be based on the annealed properties, not on the strain-hardened properties. Because of this, it usually doesn’t make sense to buy the more expensive strain hardened tempers for welded fabrications. One should design with and specify the alloy in the O temper and up-gauge as necessary.

An obvious question is whether anything can be done to restore material properties after welding a strain-hardened material. Unfortunately, the answer is almost always no. The only way to harden these materials is through mechanical deformation, and this is almost never practical for welded structures.

Heat-Treatable Alloys

The situation is somewhat different when welding the heat-treatable alloys. Alloys are heat-treated by initially heating the material to approximately 1000°F (540°C), holding the temperature for a short time, and then quenching it in water. This operation is intended to dissolve all the alloying additions in solution and hold them there at room temperature. Alloys in this condition are said to be in the T4 temper and have significantly higher strengths than the same alloy in the O temper. Depending on the alloy, "natural aging" at room temperature can lead to further strength increases over time. This takes place over a matter of days or, at most, a few weeks. After that, the properties will remain stable over decades. If one buys T4 material, it is stable and the properties will not change over the course of a lifetime.

However, most alloys are given an additional heat treatment to obtain the highest mechanical properties. This heat treatment consists of holding the material at approximately 400°F (205°C) for a few hours. During this time, the alloying additions that were dissolved in the prior heat treatment precipitate in a controlled manner, which strengthens the alloy. Material in this condition is designated as T6 (artificially aged) temper, the most common heat-treated alloy temper.

Again, the complete temper designation system is actually much more complex than this, but understanding the T4 and T6 tempers will help to overcome some of the most common mistakes made when designing aluminum weldments. It is important to note that heat treatable alloys can also be strain-hardened after heat treatment, and this can further complicate the temper designation.

Remember that the aging treatment is performed at approximately 400°F (205°C). Any arc welding process gets the HAZ much hotter than this. Therefore, welding constitutes an additional heat treatment for the HAZ. Some alloys experience an additional solution heat treatment, while other alloys become overaged in the HAZ. This results in degradation of material properties, especially if the as-welded properties are compared to T6 properties. For example, the minimum specified tensile strength in ASTM B209 for 6061 – T6 is 40 ksi (275 MPa). Most fabrication codes require a minimum as-welded tensile strength of 24 ksi (165 MPa), which is a significant degradation.

As when designing for the non-heat-treatable alloys, the designer must not use the parent material properties in design. Realistic as-welded properties must be used. It is difficult to generalize what these properties are. They change from alloy to alloy and depend strongly on the starting temper of the alloy. Most design codes contain as-welded properties for aluminum alloys and these should be used.

With heat-treatable alloys, however, there are some ways to recover some of the material properties of the parent. Figure 4 shows a plot of tensile stress versus distance from the weld for 6061, revealing curves for both T4 and T6 material in both the as-welded (AW) and post-weld-aged (PWA) conditions. The PWA condition represents a weld that is subsequently aged for one hour at approximately 400°F (205°C). Post weld aging improves the mechanical properties for both T4 and T6 starting materials. In fact, often times it is better to weld in the T4 condition and post weld age after the welding process.

There is one final alternative to discuss. If after welding, the structure is given a complete heat treatment (i.e., solution treat at 1000°F [540°C], quench, age at 400°F [205°C]), all of the material properties (even in the weld) will be recovered and T6 properties will be obtained. This practice is frequently followed on small structures such as bicycle frames, but it is impractical for larger structures. Furthermore, the quenching usually causes enough distortion of the structure that a straightening operation is necessary before aging.

Conclusions

In the design of welded aluminum structures, too often the differences between steel and aluminum are not taken into account. To recap, common mistakes include:

Not all aluminum alloys are weldable. In general, the least weldable alloys are also the strongest alloys

The weld will rarely be as strong as the parent material

The HAZ will have O temper annealed properties for non-heat-treatable alloys regardless of the initial material temper

For the heat treatable alloys, the as-welded properties will be significantly lower than the properties of the T6 alloy temper

Post-weld heat treatment can help to restore the mechanical properties of welds in heat treatable alloys