College of the Canyons California Community College Prepares Welding Workforce

Incorporates new automated technology curriculum into degree/certification programs

At College of the Canyons in Santa Clarita, California, welding has been a cornerstone of the school’s career technical education (CTE) program for more than 30 years – a symbol of the college’s commitment to fostering regional economic development on numerous levels.

“A core mission of many community colleges, including those in California, is to provide career technical education,” explains Kristin Houser, College of the Canyons’ division dean of CTE. “These programs offer the training needed for sophisticated, high-paying jobs. Our welding technology program is a poster child for one that is done well and achieves this mission.”

Led by department chair Tim Baber, the college’s welding technology program strives to provide a number of industries – construction, aerospace, fabrication, piping, petrochemical, motorsports, repair and maintenance, ship building and heavy equipment – with skilled welders trained in the latest welding techniques, on the newest equipment.

“There’s a high demand for skilled welders, not just in California, but also nationwide,” Baber says, noting that the program serves between 200 to 350 students seeking welding training at any given point in time, either through the two-year associate’s degree program or through continuing education programming, which offers a certificate of achievement and six certificates of specialization.

The college’s two-year Associate of Science degree in Welding Technology offers a number of American Welding Society (AWS) certifications and also is SENSE (Schools Excelling through National Skills Standards Education) certified. The college also is an AWS Accredited Test Facility (ATF) and provides local certification through the Los Angeles County Department of Building and Safety, leaving welders who complete a degree or certification program well equipped to perform any welding job in the region.

Additionally, College of the Canyons plays an integral role as a regional training partner in the national Weld-Ed program, funded by a grant from the National Science Foundation, that trains welding instructors to empower future generations of welders. The program is facilitated by the National Center for Welding Education and Training, a dynamic partnership between business and industry, community and technical colleges, universities, the AWS and government that is based at Lorain County Community College in Northeast Ohio.

Because of the important role that College of the Canyons plays in the Weld-Ed program, as well as feeding a highly skilled welding workforce to businesses throughout Southern California, Houser and Baber recognized that the school needed to do even more to prepare for the future. They decided to add a welding automation certificate to the department’s already-in-depth curriculum, not only for students learning the welding trades but also for the instructors who teach them across the region.

To accomplish this, the college set out to obtain automated welding equipment and develop an interactive curriculum around the automated welding cells – a curriculum that did not exist. Lincoln Electric stepped in to assist on both fronts.

“When researching the available welding automation cells, it became evident that Lincoln Electric’s Automation Division provided superior turnkey solutions to meet the equipment needs for our project,” Baber said, adding that virtually all of the other welding equipment on-site is from Lincoln Electric.

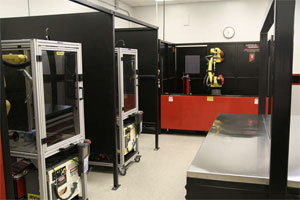

The equipment – four pre-engineered Lincoln Electric Robotic Welding Education Cells and two System 5 fixed table systems – was purchased through a California Community Colleges Chancellor’s Office EWD Industry-Driven Regional Collaborative Workforce grant.

“We couldn’t afford to have an integrator come in and custom build the ultimate robot system,” Baber says. “Here’s a cell that’s ready to plug in and play. I can roll it into the classroom, show students what to do, and give them a hands-on experience of how automated welding works.”

The other new robotic welding component, the Lincoln Electric System 5 single-zone, fixed table system, comes completely assembled and ready to use. It incorporates the Lincoln Electric Power Wave® i400 power source, AutoDrive® 4R100 wire drive, as well as a FANUC® ARC Mate® 100iC Robot with six high-speed axes for maximum flexibility.

Lincoln Electric’s Automation Division also worked with the College to develop a welding automation curriculum that easily can be modified or expanded if the program changes or if the college adds new or additional equipment.

“You can’t build a program around one cell or do just a straight classroom lecture on automated welding,” Baber says. “Our students need to have a hands-on approach where they get in and use the equipment and understand the programming techniques. We also want to instruct them on the maintenance aspects of this technology. This new curriculum reflects all of this and is in line with entry level welder specs, as well as more advanced certifications and training.”

Baber says he is in the process of developing a curriculum that incorporates virtual reality welding into the automated welding program.

“I plan to use the VRTEX® 360 as a teaching tool for understanding the process parameters of GMAW,” he explains.

Baber and Houser credit a strong and continually growing partnership with Lincoln Electric, as well as other industry leaders, as a key component in the development of College of the Canyons’ welding program. The program complements other areas of study, including metal fabrication and robotics, giving students the ability to create a technical degree program that suits their interests, as well as one that provides a well-trained workforce for the region.

“We take economic development seriously at our college,” Houser says. “We help employers fill entry level jobs with well-qualified students and also provide workforce training and development programs. It all comes down to continually helping current welders build on their skill sets and also to attracting a quality skilled workforce of the future.”

Recently, the college held its own “Discovering Careers” program showcasing all of the college’s CTE offerings, bringing more than 3,000 middle-school and high-school students and their parents to the campus. Welding demonstrations were one of the event’s most popular activities.

The 16-foot former carnival concessions trailer, featuring eye-catching graphics, includes five Lincoln Electric welding machines for live, hands-on demonstrations, a generator to power the equipment, and a video monitor that delivers a presentation designed to show young minds why a career in welding is cool.

On these outings, Baber also brings along the VRTEX® 360, which he views as an important tool not only for classroom teaching but also for recruitment. He says that during recent outreach events and junior high institute workshops, students have been excited to try welding in virtual environments.

“We usually have kids lined up all day for that,” he says. “In fact, many of the participants who tried the VRTEX® 360 during our outreach events became motivated to try the hands-on live welding processes that were available on our welding road show trailer. We hook many kids through the virtual reality, encourage them to try the real deal, and ask them to consider a career in welding. We need to engage them early because they truly are the welding industry’s future.”

(Pictured left to right) From College of the Canyons: Marty Coronel, Robert Serrano, William Mouton, Tim Baber, and Dale Watkins. From Lincoln Electric: Sergio Montel and Albert Castillo.