Largest Diameter FCAW Wire for Out of Position Welding

Q: I need to weld out of position with a mild steel flux-cored wire, and want to do it as fast as possible. Therefore, I am thinking of a 5/64” (2.0 mm) or larger diameter wire. Which size and type of wire would you recommend?

A: First, keep in mind that there is a limit to how big of a weld puddle you can carry out of position. Always think of welding in terms of liquid metal and gravity. When welding “in position” (i.e. flat and horizontal positions) you are welding with gravity. The weld metal is resting on the plate and you can carry a much bigger puddle while it is in the liquid state. This is especially true in the flat position. Even in the horizontal position, gravity pulls the weld metal to the bottom side of the joint. Therefore, the maximum size uniform single pass horizontal weld that can be made is smaller than a uniform single pass flat weld. When welding “out of position” (i.e., vertical and overhead positions), you are welding against gravity. Now you are much more limited as to the size of the molten puddle you can carry. How fast the weld metal solidifies and the support of a fast freezing slag system, if present, are keys to successful out of position welding.

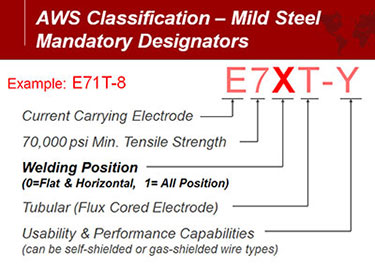

Just like with stick electrodes, the key to a flux-cored wire’s ability to weld out of position or not is dependent on its slag system. Some wires have a fast freezing slag which helps support the weld puddle and allows you to weld out of position or against gravity. Other wires have a slower freezing slag system and therefore are used for flat and horizontal welding positions only. The American Welding Society (AWS) classification number for a particular flux-cored electrode will tell you, among other things, its intended welding position. Figure 1 shows the key to the AWS classification nomenclature. The second or third digit in the number (depending on wire's minimum tensile strength) indicates welding position. A "0" means flat and horizontal only positions or a "1" means all position.

Figure 1

Flux-cored wires are of two basic types, self-shielded (FCAW-S process) and gas-shielded (FCAW-G process). All position flux-cored wires are generally made in smaller diameters. Regarding self-shielded flux-cored wires, while a few are available in 0.045” (1.1 mm) size or smaller, most range in size from 1/16" (1.6 mm), 0.068" (1.8 mm), 0.072" (1.8 mm) and 5/64" (2.0 mm). The largest all position classified FCAW-S electrode that can successfully run out of position is 5/64" (2.0 mm). Gas-shielded flux-cored wires are primarily available in 0.045" (1.1 mm), 0.052” (1.3 mm) and 1/16" (1.6 mm) diameters. Therefore the largest all position classified FCAW-G electrode that can successfully run out of position is 1/16" (1.6 mm). On the other hand, in position wires for flat and horizontal welding are made in larger diameters. Typical in position wire size for the FCAW-S process are 5/64" (2.0 mm), 3/32" (2.4 mm), 7/64" (2.8 m) and 0.120" (3.0 mm) and for the FCAW-G process are 1/16" (1.6 mm), 5/64” (2.0 mm) and 3/32" (2.4 mm).

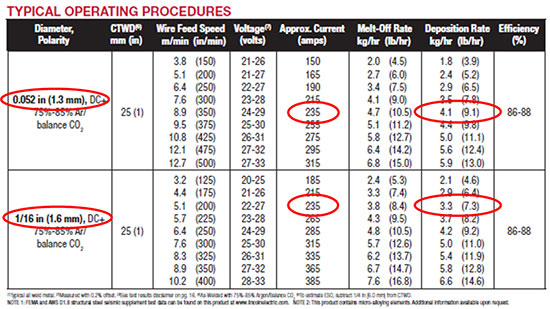

Referring back to your question, it sounds like you want to run a larger diameter wire to get maximum deposition rates and thus maximum productivity. However, bigger is not always better. True, if you were welding in the flat position where you could run at the upper current limits of a given wire, the larger diameter wire would have a higher deposition rate capabilities over a smaller wire size. However, out of position welding has to be done at lower current levels. It is difficult to weld at over 250 - 300 amps before there is just too much liquid metal to handle against the force of gravity. So at lower and equal current levels, a smaller diameter wire can often have a higher deposition rate than a larger diameter wire. This is because the smaller diameter wire has a smaller cross sectional area and thus higher current density. The smaller wire will melt at a faster rate, allowing you to run much faster wire feed speeds than the larger wire. Often the much faster wire feed speeds with the smaller wire results in a higher deposition rate than the larger wire; again with both wires at the same current level. Look at consumable literature of various flux-cored wires and compare two sizes at equal currents. You will often find the smaller diameter has a higher wire feed speed and corresponding deposition rate. This point is illustrated in figure 2, which shows typical operating procedures for an all position E71T-1M / E71T-9M gas-shielded flux-cored wire.

Figure 2

In addition, a smaller diameter wire can be a little easier for the welder to handle. A 5/64" (2.0 mm) self-shielded flux-cored wire or a 1/16" (1.6 mm) gas-shielded flux-cored wire can be challenging to handle out of position, especially for less experienced welders. Instead, the 0.068" (1.8 mm) or 0.072" (1.8 mm) sizes for FCAW-S wires and 0.045" (1.1 mm) or 0.052" (1.3 mm) size for FCAW-G wires can be easier to handle.

Now a 5/64" (2.0 mm) FCAW-S wire or a 1/16" (1.6 mm) FCAW-G wire size often works best for applications where you need one wire size for both out of position welding and in position welding. This allows you achieve good deposition rates for out of position welding, and then for in position welding turn up the procedures to the wire's upper wire feed speed and resulting current levels and take advantage of its higher deposition rates. Dual schedule guns and dual schedule wire feeders are ideal for taking advantage of this scenario.